One day in the spring of 2014 the shop phone rang. On the other end of the line was Dave Austin, a British car collector from upstate New York. He told a crazy story about finding a stash of cars deep in the back woods of someone’s property, and after making a deal to purchase the lot was told the sale included a “rusty old motorcycle”. Turns out the bike was a 100% complete ’71 Norton Commando. Dave wanted NYC Norton to do the “resurrection” on this one. The Cafe Racer TV folks got wind of this and asked if we could wait to do up the bike to coincide with their film schedule for their upcoming new season. Sure thing. We were busy anyway, so this would dovetail nicely into the shop schedule later in the summer.

Now, as I write this, the show has already aired (February 4, 2015) and it’s definitely worth a watch (The show can be downloaded in HD from Amazon and iTunes). I won’t try to rehash everything here that the show already covered. But perhaps I can give a little insight into the behind the scenes and techie stuff the show glosses over, as well as some of the thinking going into this bike.

We finalized a date when the bike would come down from Saratoga Springs and we prepared for the hullabaloo that was about to ensue. But I’ve done Cafe Racer TV before and It’s a pretty easy-going production, and fortunately this shoot was no different. Dave pulled up with the bike in the back of this truck, followed by Mike Seate and a crew of 4. The bike was absolutely filthy and everything visible had rusted. But it was complete. 100% complete – tank/seat/mudguards/mirrors – everything was there. This begins the existential dilemma – how do we do a “custom bike” to the customer’s liking without going too far off the rails?

Dave was after a performance bike with some of the hallmarks of period racers of the day. One thing he really wanted was a larger “Isle of Man” tank, but I iterated any Commando that raced at the Isle of Man generally had a “Production Racer” style to it, not a 5-Gallon alloy Manx style. He’d brought in a lot of photos off the internet of bikes he liked (not all Nortons), as well as forwarded emails with photos attached as we went along throughout the entire build. But there were a couple of bikes that stood out to me that Dave really liked, in particular a Norton Wasp racer (if you google this you will see what I mean) I’d seen on the internet. It is a big, thick framed unique racer that has some great lines. This was a good inspiration and starting point.

As the cameras rolled, Jon and I did the initial teardown of the bike in about 4 hours. We’d emphasized in advance to the producers we’d be very low key. We don’t argue, we don’t shoot sparks, or use angle grinders, we don’t have beards, and we like to work with micrometers instead of with hammers. They understood and reassured us it would be come off as such. As we worked we realized more and more how pristine of a Commando it really was. Yes, everything would need to be cleaned, and most of the steel was long gone, but the aluminum was in good shape, and as the outer covers came off it became apparent the bike was as stock as can be and had little evidence of dreaded previous owners. It deserved to come back to life. We quietly agreed we’d try to keep the spirit and soul of it intact and still give it a new lease. Our mission.

After it was all down to bits, the cameras and crew packed up and left us to our work. Jon and I talked about this project for many days after, working to formulate the best plan to make this something special while keeping our focus and Dave’s requests on the same level.

One issue we knew we’d quickly address was the fuel tank. The bike had a Commando Roadster fiberglass tank and there was no way it was ever going to hold fuel again, particularly with the Ethanol in today’s gasoline. NYC Norton has had many bikes come in after folks had run Ethanol through their old fiberglass tanks, gumming up carbs, sticking valves, and destroying motors. So for this build a custom steel tank would be made. We have worked for years with local metal-pounding curmudgeon Dick Gambino and knew he was the go-to guy to help us fabricate something nice. Dick always has strong opinions, but he’s very patient with us and ultimately delivers what we need. We had a few old tanks to get moving with, but agreed an old rusty Kawasaki KZ tank Dave supplied would be a great starting platform. Back in his shop Dick cut the center out to narrow it up, cut the head out to push it forward, cut the knee panels out to tighten up the rear, and ultimately came up with the brilliant idea of welding in the bottom from a trashed steel Commando Roadster tank Dick happened to have lying around his shop onto the bottom our KZ tank. This all was a bit of a process and took a couple of months to get something ready to set on the bike for initial fitment (More on that below).

In the meantime the rest of the bike needed to be built. We stripped the frame and checked it for straightness and cracks. It passed with flying colors. We stripped all the other chassis components and got them ready for powdercoat. The frame would be gloss black. The battery tray, swingarm, cradle, and front mount all got the treatment. We would use MK3 vernier Isolastics, a good rod-end headsteady, and proper alignment of all the components insured. We agreed the hubs would be a flat black powder to resemble the magnesium hubs used on many of our race bikes. Once back from the powdercoater we built them onto 18″ Excel flanged alloy rims with stainless spokes and nipples; a WM2 up front and WM3 on the rear, both shod with Bridgestone BT45 tires. Ikon/Koni 7610 shocks on the rear would be the perfect damping. We would be fitting our NYC Norton yokes (triple clamps) with clip-ons and custom leather grips, and using our NYC Norton Rearsets with hand-made brackets to adapt them to the Commando Z-Plates.

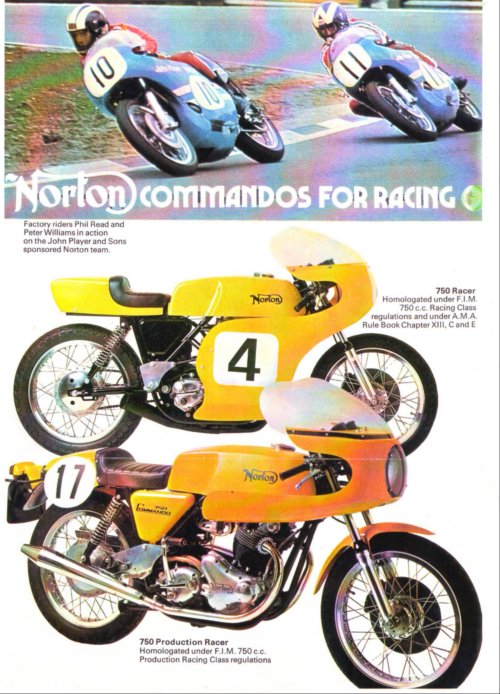

One of the biggest philosophical issues we had was the rear end and seat of the bike. The au courant look of custom bikes out in the world these days is to have a stubby/bobbed/minimal rear seat moved very far forward. I think that’s where Dave initially wanted to go with the look. But street-going Commandos have a very long rear frame loop, and if one tries to disguise this with an extended seat hump enveloping the entirety of the rear loop it starts to look way too long and silly. The factory Production Racers used a really nice shorter seat that curved backwards onto the rear mudguard creating a great classic line while retaining the frame loop, mudguard and tail light. We liked this idea and presented it to Dave by way of a Norton Factory brochure from the early ’70s, but he was immediately interested in the styling cues of the Norton “Formula 750” period racers also shown in this brochure, whose rear end implemented a shortened frame loop (pictured behind the standard Production Racer in the brochure below).

Okay. A compromise. We cut the rear loop (it was hard for us to do, believe me) about 4″ in and reinforced the frame with a welded-in cross-bridge near the shock mounting points to keep any potential flex to a minimum. But now it was time to find a decent seat section. And part of that meeting-in-the-middle would be to use a Norton Production Racer seat pan shortened in the front and shaped in the rear, and moved forward on the bike giving the more aggressive and minimal line Dave was after.

The motor and gearbox builds are always the easiest parts of a project because there is no ambiguity in the process. The motor came down, all the way down, and was measured and blueprinted/documented. The crank was split and sludge trap cleaned, cases tumbled, journals measured, new bearings, end float set, rods checked, cam checked, bores measured and overbored, cylinders painted, new pistons with proper piston-to-wall set, ring gaps, head completely gone through with new Black Diamond valves, seats cut, new guides, seals, etc. The head was skimmed .040″ to up the compression and give a bump in performance. The gearbox was in great shape and needed little more than seals, bearings, and bushings, along with the NYC Norton kickstart shaft seal mod and shift shaft seal mod. The entire motor and gearbox builds were filmed by us over the course of a couple of days using statically mounted GoPro cameras provided by the producers, placed on our benches around the shop, to capture the build. Once finished we uploaded the footage onto the TV show’s servers and were really pleased that we got a lot of the finer details that NYC Norton specializes in captured on film. How much would end up actually in the show we didn’t know (and now we know not very much – the entire motor build appeared in the episode as a time lapse that runs for about 10 seconds), but at least it was there and documented.

The TV show folks were calling and wanted to set up a date to come back and shoot “The Build”. I say that in quotes because there simply is no way to build a bike in one or two days with cameras rolling. Essentially the major components needed to be built in advance, then taken down and prepped to do them up again in a short amount of time for the the magic of TV. The motor was done and ready, as was the gearbox. The frame and bits were ready, the forks awaiting assembly for the cameras.

But where was the tank?? Dick was down to the wire on this one. We pushed the shoot date back as far as the crew would allow, but they needed to get on with the show, so we started shooting without a tank in hand. Dick had promised to deliver the tank to us 2 days before the cameras arrived so we could go through it together, and make any last minute changes, but no such luck. We went ahead with things and prayed that Dick would show up at some point with a finished product. If we ever had any drama during the build, this was it, and this drama didn’t make it to the episode (which is fine by me).

Back to the shoot: The day started at 8am with the arrival of the film crew. Things went along really well overall, and the bike came together rather quickly. Obviously for the sake of the cameras we were focusing on big things – frame and swingarm/cradle go together, shocks go on, gearbox goes in, motor goes in, primary comes together, yokes go on, Jon assembled the forks for the cameras and we slid them in and set their height. The wheels went on. At one point I looked over and felt all of a sudden the pile of parts we’d been working on was really starting to look like a motorcycle.

During the process the crew never really asked anything of us. We never had to stop and re-shoot things, or clarify what we were doing, we just did what we did and they worked around us. I think they’d all done this before. By the end of the day we had the working core of a beautiful Commando up on the lift. We had already started modifying the Proddy Racer seat to get it in place, but without the tank in hand we couldn’t do a lot of trimming and shaping necessary.

Finally at about 7pm the knock on the door came. Dick walked in with our tank, looking like he’d been up for weeks. It would be the first time we would lay eyes on it since handing the ratty old Kawasaki tank over to him a few months earlier. This was all captured by the cameras and seen on the show as it played out. But I’m not sure the actual tension was fully realized on the small screen. We were definitely on the spot here with the cameras rolling and fitting of the tank to the frame for the very first time. Never again will we let things get to this point. In any case, the tank fit. but needed some love. The bottom line was rough and would require raising it almost an inch to meet the line of the seat. But it was good enough for TV, and everyone could rest easy.

The rest of the evening was spent doing “Green Screen”, which is essentially single-person interviews in front of a large green screen as the name implies, so an image can ultimately be digitally imposed behind for the show. I did my bit, then Jon, then Steph. I’m not sure how she felt coming into the job so recently and being thrust into the spotlight, but she handled it like a pro.

The day was done, the crew was happy, and away they went with their hands full of footage. The bike was 90% done and 90% to go. The very next day the entire thing was torn down again so we could do it up for final assembly. There’s just too much that can get overlooked when you’re working in front of cameras, and we had to deliver a bike that went fast safely to our friend Dave.

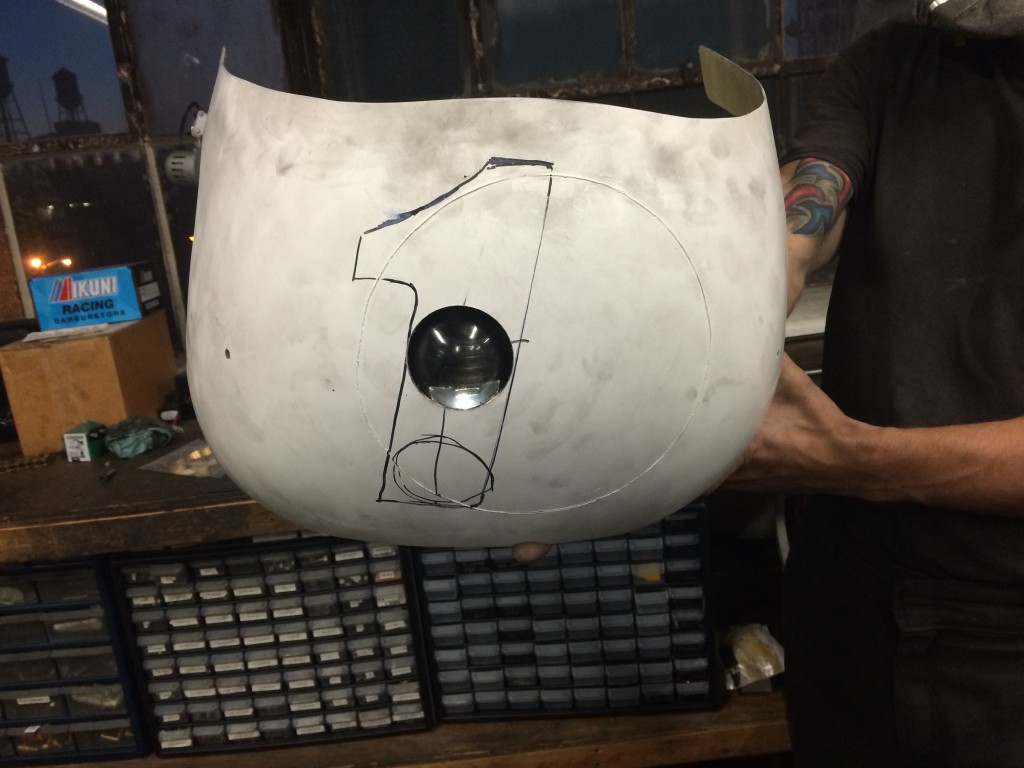

Dick had the tank back to us within a week or so with the final modifications and we started discussing paint schemes with Dave. He had mentioned all along he wanted some sort of red or burgundy and we started looking at a lot of paint chips and samples and lots of modern cars with candy colors. I was having a hard time visualizing such a big pop with such a classic so we pushed for something a little more traditional. We sent the tank up to Brent Budgor at Vintage Vendor. Brent does a lot of painting for us and I’ve yet to find a small subcontractor who is as good to work with. Together we worked through many different colors and schemes. We knew the Norton logo would be underlaid, but the rest was undecided. In fact it was Brent who suggested the 2-tone burgundy/black combo we ended up with. When we suggested certain paint codes to him he would make alternate suggestions, and a lot of back and forth happened. But it was one suggestion in particular that resonated with me – a ’66 Mustang burgundy. Yes, without question this was the right way to go, and everyone agreed. So the paint scheme mockup began. In the meantime Jon and I had to get the fairing fit and drilled and shaped so we could get it up to Brent for paint. Dave wanted number roundels on the bike and surprisingly requested the #17 painted on (he never did explain why), but I was fine with that as it’s my own racing number here in the US. A no-brainer there. But a hurdle was to get the little endurance racing light mounted on the steering head out of the way of the forks and try to keep its cutout in the nose of the fairing within the stripe of the “1” so to be invisible.

It worked, but not without a fight. We had to kern the numbers and rotate them quite a bit to get the 2 digits to align. Again, I don’t know if I could’ve worked through this with anyone other than Brent. He was patient and always sent photos of what he was doing along the way. No surprises. And Brent did some inhuman work on the tank. He skimmed it and dressed it, and when he sent us a photo of the mockup of the tank right before paint I was so very happy and knew it was going to be quite special. Would it be stating the obvious if I said making the bike look pretty is extremely rewarding?

In the meantime, we were back at work getting the thing to be a real, working motorcycle. The rearsets presented a challenge simply because the Commando primary and gearbox are wide so the whole assembly would need to be spaced outboard quite a bit. This meant fabricating up some brackets to mount the rearsets, then mount those brackets to the existing Z-plates.

During the process of the rest of the build, Dave left us to our own devices. Once the tank and seat design were hammered out, and the color scheme decided, the rest was on our shoulders to build up the bike as an NYC Norton build should be. The producers of the TV show wanted to shoot the “reveal” of the bike in early October, and while that seemed to be an attainable date if we didn’t have anything else going on in the world, it fell smack-dab into the middle of our preparation for Barber (see our blog post on Barber about all that went into that weekend). Things were stressful in the shop as we can’t stop the other jobs that we had going, but little by little we chipped away at it all and got the bike in running order. When the tank and seat arrived back from paint, the bike had been wired with a custom harness and was ready for the jewelry to be hung.

Wow… it was for real.

We needed to put some good test miles on the bike and get it all dialed before we could go on TV with it. Since our shop is a mere 2 miles away from the biggest city in the USA we have to travel to quite a ways to get to any quality test riding roads. We have our top-secret proving grounds about 30 miles outside the city, and made several trips out over the next days, as we always do before a bike is ready to hand over to a client.

Each test bike ran almost flawlessly. We’d done several heat cycles in the shop and had the carbs dialed quite well beforehand, so each time putting miles on the bike was easy and fun. It handled like a dream, was very steady, tight, and confident, but was a quick turning animal. If Dave didn’t want the bike in the end, we were ready to buy it from him!

The fairing came in from Brent and we fitted it up and everything was in place. The only issue remaining was the speedo. The odometer was working but the indicator was not. No time to get it dealt with before the shoot (it can take a while for our speedo shop to turn something around), so it had to be. But that was a small glitch in an otherwise perfect bike. The speedo has since been rebuilt and working well.

Onto the final shoot: Once again the camera crew showed up at 8am, and Dave arrived a short time later. He had not seen the bike (and didn’t want to) since the day he dropped it off, other than a couple of mockup photos emailed here and there, so this was to be a genuine surprise. We wouldn’t have liked faking the “reveal” and the TV show folks agreed. The crew assembled at the loading dock and did some initial interviews with Dave while we kept the dock door closed until the moment of glory. Then it came – Steph opened the door, I rolled the bike out, and there it was. Every reaction seen on the show is real. Nope, not a lot of drama, but certainly a genuine enthusiasm. And for that I am happy not to have gone Hollywood.

We then loaded the bike up and headed out to a very scenic spot to do the test ride. As you see on TV, it was a little nerve-wracking when Dave took off on his initial ride. He is a car guy – his gloves and helmet are auto racing bits – and I wasn’t sure he even knew how to ride. But he did! And ride he did! He took off and didn’t come back for a half an hour. I was seriously worried. I mean, anything could’ve happened. Did he get stuck at a light and kill the bike? Did he wipe out? Then he came roaring back with a smile under that helmet and all was good!

We did a few more shoots with onboard cameras, following alongside the bike, etc. Each time Dave came back it was nothing but grins.

So, that’s really it. I was quite pleased how the show came out. We didn’t break anything or blow anything up. The bike ran great and looked great, and that’s all we wanted. I only wish Brent would’ve gotten some screen time. We filmed his delivery of the parts, but he never got added into the storyline for the show. Thanks, Brent. The paint is stunning.

That’s the story of the School Bus Bike.

Thanks for all who have reached out in support. Time to go back to work, doing what we do, which we love to do, by the way.

– Kenny Cummings

February, 2015